|

|

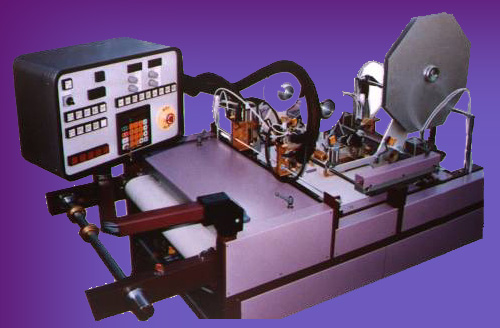

Bead and Strip Coating machine

Production Capacity

about 1'000'000m year

|

|

Technical Data

- Conveyor width 2x300 mm

- Distance between axes 1'200 mm

- Speed: 0-24m/min electronically-controlled gear

motor

- 2 un-rolling units for bands and strips.

- 2 application heads in the X - Z axes, controlled by

drive-screw

- 2 un-rolling units for the cover tape with cutter to split

the silicon coated PU Band in two strips

- 4 cooler units to reduce the temperature of the applicated

glue from 120°C to 80°C.

- 1 cutter unit for bands and strips and rolling device

for 100 mm cardboard cores

The

presence of the strips is monitored by sensors, which stop the conveyor

and the glue pump when the strip is not present All electric cables are

fitted with connectors. The machine is divided into various modules

which can be easily dismantled

|

|

Bead Coating:

|

With

this machine, two sealing profiles can be simultaneously fully

automatically coated with hotmelt glue at a speed of 15m/min. The two

10mm wide adhesive strips are protected with a 24mm siliconised

PU-bead, which is cut logitudinally by a razor-edge. The bead is driven

by a

electronically-controlled conveyor belt with position-controller, in

which the desired length of bead is

programmed. When the programmed length has been coated, the bead is cut

with a specially cutter and rolled onto a core. |

|

Using this machine you can also

coat your products with glue dots, lines or areas.

-

Additional application heads with various nozzles can be fitted.

- Metal

plates or other sheets can be coated .

-

Hot-melt glue and other adhesives can be coated at the same time.

-

Flexible insulation material from the roll can also be fitted to a

fixed base.

-

There are many other

possibilities.

-

Contact us - we can help to improve your fabrication

|

|

| Strip coating: |

The

strips are delivered on rolls with lengths of 150m and widths from 80

to 550 mm. Depending

of the tape width, one or two adhesive strips are applied and if

necessary, separated by a spacer tape. The finished, coated and rolled

strips with length of 10m are rolled on a cardboard core of diam. 100mm

and sealed with an adhesive tape. |

|

|

|

|

|

|

|

![[UB Seal-Coating Machines AG]](pictures/SC.gif)

![[UB Seal-Coating Machines AG]](pictures/SC.gif)